Company Details

Company Details

| Unit Price: | USD 3000 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,DDU |

| Min. Order: | 1 Set/Sets |

Brand: JIEMA

Packaging: Plywood

Productivity: 100000

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000 sets

Certificate: ISO

Port: Guangzhou,Shenzhen

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,FCA,DDU

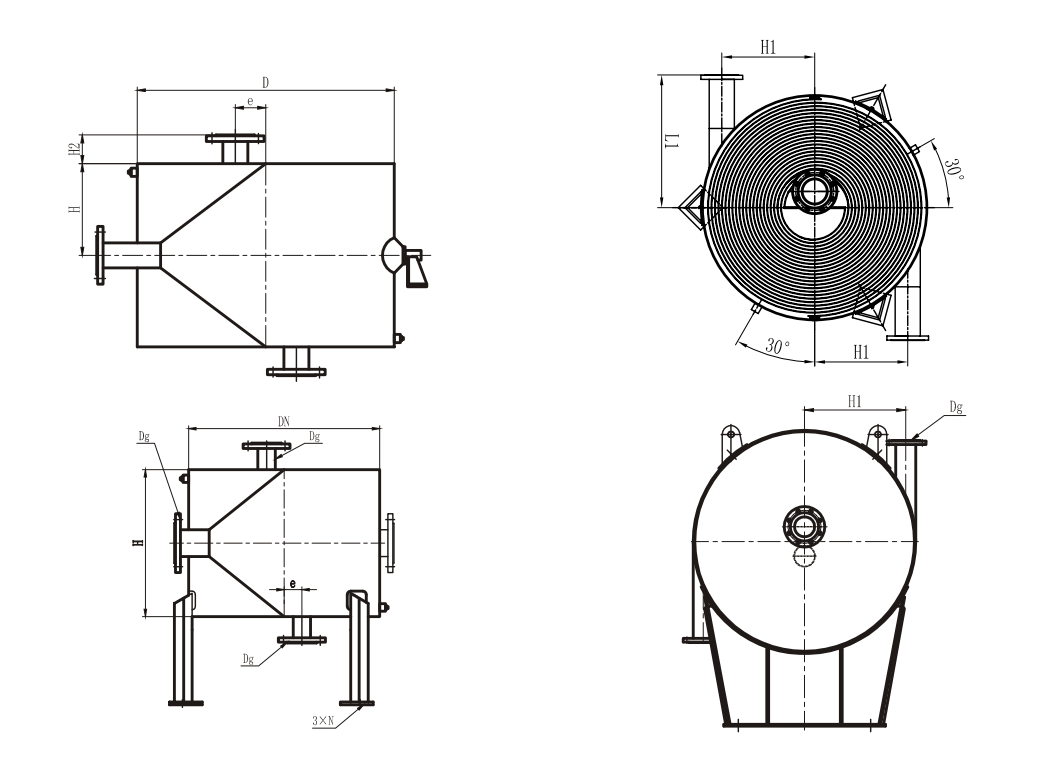

The Spiral plate heat exchanger is a specially designed heat transfer device that is widely used in palm oil production lines for both cooling and heating applications. Its unique design allows efficient heat transfer between two fluid streams with very little heat loss, making it an ideal solution for optimizing energy usage and reducing operating costs.

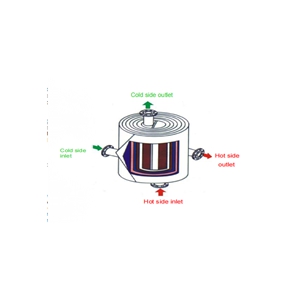

The Spiral Plate Heat Exchanger operates on the principle of counter-current flow, where two fluids flow in opposite directions across a series of coiled plates. As the fluids pass through the plates, heat is transferred from the hot fluid to the cold fluid across the metal surfaces, resulting in a temperature equilibrium between the two fluids. The spiral configuration of the plates ensures high turbulence of the fluids, creating maximum contact between the metal surfaces and the fluids, resulting in effective heat transfer.

In palm oil production lines, the Spiral Plate Heat Exchanger is used in the cooling system to reduce the temperature of the extracted palm oil after it has been heated in the sterilizer and digester. The cooled oil is then sent for clarification and separation before being stored or used for further processing.

The Spiral Plate Heat Exchanger is also used in the heating system to heat up the incoming palm fruit bunches and water for the sterilization process before extraction. The heat exchanger preheats the water before sending it to the sterilizer, reducing the energy required to bring it to the desired temperature.

Product Categories : Spiral Plate Heat Exchanger