Company Details

Guangdong Jiema Energy Saving Technology Co.,Ltd

- [Guangdong,China]

- Business Type:Manufacturer

- Main Markets: Africa , Americas , Asia , East Europe , Europe , Worldwide

- Exporter:21% - 30%

- Certs:ISO14001, ISO9001, CE, Test Report

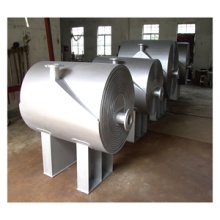

- Description:Spiral Plate Type for Heating,Spiral Structure for Cooling,Spiral Heate Exchanger Applications