Spiral heat exchanger is a type of heat transfer device that is used to efficiently transfer heat between two fluids. It consists of two parallel flat plates that are wound in a spiral pattern to create a series of channels through which the fluids flow. The spiral design of the heat exchanger makes up one of its most common applications in the heating of sludges, emulsions, and slurries.

Spiral heat exchangers are commonly used in a variety of industrial applications, including chemical processing, power generation, and food and beverage production. They are particularly well-suited for applications where high heat transfer rates are required, or where there is a need to transfer heat between fluids with very different properties.

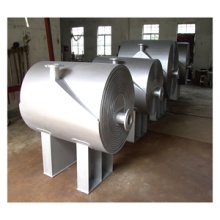

(Spiral Plate Heat Exchanger workshop)

Sludges, emulsions, and slurries are complex mixtures of solids and liquids that are often difficult to heat using conventional heat exchangers. These mixtures have a high viscosity and tend to form deposits on the heat transfer surfaces, which can reduce the heat transfer efficiency and increase the maintenance costs.

Spiral heat exchangers are ideal for heating sludges, emulsions, and slurries because of their unique design. The spiral channels in the heat exchanger create a turbulent flow that enhances the heat transfer coefficient and prevents the formation of deposits on the heat transfer surfaces.

(Spiral heat exchanger in test and inspection)

In addition, the spiral heat exchanger has a large surface area per unit volume, which allows for a high heat transfer rate even in highly viscous mixtures. This means that the heating process can be completed quickly and efficiently, reducing the overall energy consumption and operating costs.

Spiral heat exchangers are also highly adaptable and can be customized to meet the specific requirements of different applications. They can be made from a variety of materials, including stainless steel, titanium, and other alloys, to provide resistance to corrosion and abrasion.

Overall, the use of spiral heat exchangers for heating sludges, emulsions, and slurries offers numerous benefits, including increased efficiency, reduced maintenance costs, and improved product quality. As such, they are an essential component of many industrial processes and are expected to continue to play a critical role in the years to come.

Product Categories : Spiral Plate Heat Exchanger