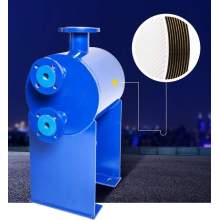

Jiema SPS Plate and Shell Heat Exchanger's corrugated plate and shell design is of compact structure, have high-performance in heat exchange, and of small size, wide temperature range, while it can withstand severe thermal shock and pressure fluctuations. Therefore, it is widely used in machinery industry applications. Similar products of this type are Disk and Shell Heat Exchanger and Fully Welded Plate and Shell Heat Exchanger.

To list our applications here, we have Liquid Heat Exchange Process, Gas Cooling Process, Oil Cooling Process, Gas Dryer, Laser Welding Cooler, Refrigeration Water Cooler, Vacuum Pump Cooler Evaporator Of Cold Laser Cutting, Hydraulic Mechanical Dryer, Water Cooler and Heater...

Specification of SPS Plate and Shell Heat Exchanger

Design Temperature: -195-550℃

Design Pressure: Vacuum-100.0bar

Single plate area: 0.022-2.0m²

Plate Thickness

| Working Pressure

|

0.6mm

| 10-25bar

|

0.8mm

| 10-63bar

|

1.0mm

| 40-100bar

|

Advantages for Disk and Shell Heat Exchanger Manufacturing

After years of accumulation of technology and practical application experience, Jiema has independent development capabilities and patented technology. It has been committed to the development and use of energy-saving and environmentally friendly heat exchange equipment, and has passed the TUV/ISO:14001:2004 environmental system certification, obtained the Guangdong environmental protection product certification.Independent research and development of plate and shell heat exchanger products and their automated manufacturing equipment, and obtained a number of national invention patents, using the international advanced fully automatic plasma welding process for product-heat core welding. and the produced plate/plate and shell type replacement Heaters. plate/plate shell heat exchange units,. and half-volume heat exchangers have all reached the international advanced level.

After years of accumulation of technology and practical application experience, Jiema has independent development capabilities and patented technology. It has been committed to the development and use of energy-saving and environmentally friendly heat exchange equipment, and has passed the TUV/ISO:14001:2004 environmental system certification, obtained the Guangdong environmental protection product certification.Independent research and development of plate and shell heat exchanger products and their automated manufacturing equipment, and obtained a number of national invention patents, using the international advanced fully automatic plasma welding process for product-heat core welding. and the produced plate/plate and shell type replacement Heaters. plate/plate shell heat exchange units,. and half-volume heat exchangers have all reached the international advanced level.

FAQ for Fully Welded Plate and Shell Heat Exchanger

1.How does a Shell and Plate Heat Exchanger work? For instance, say your Shell and Plate Heat Exchanger or Fully Welded Plate and Shell Heat Exchanger?

It is the same as Plate And Frame Heat Exchanger. Two fluids flow into different channels of our Shell and Plate Heat Exchanger and then share heat spontaneously. Things worth mentioned is that our Fully Welded Plate and Shell Heat Exchanger, or Disk and Shell Heat Exchanger can endure 550degree and 100bar at the most.

2.Difference between Shell and Plate Heat Exchanger and Plate and Frame Heat Exchanger?

The two share several similarities. To name just a few, they are both very efficient and have economic space area, and above all, can be removed for the convenience of cleaning. And now let us move to the differences. Plates for Plate and Frame Heat Exchanger are piled up to form a stable channel. Shell and Plate Heat Exchanger’s plates, on the other hand, is welded to create a plate bundle. It is also for this reason that SPS Plate and Shell Heat Exchanger or Disk and Shell Heat Exchanger is more suitable for high temperature and high pressure application since it has no gaskets. Side note is that Shell and Plate Heat Exchanger also has low fouling factor.

Product Categories : Shell and Plate Heat Exchanger

After years of accumulation of technology and practical application experience, Jiema has independent development capabilities and patented technology. It has been committed to the development and use of energy-saving and environmentally friendly heat exchange equipment, and has passed the TUV/ISO:14001:2004 environmental system certification, obtained the Guangdong environmental protection product certification.Independent research and development of plate and shell heat exchanger products and their automated manufacturing equipment, and obtained a number of national invention patents, using the international advanced fully automatic plasma welding process for product-heat core welding. and the produced plate/plate and shell type replacement Heaters. plate/plate shell heat exchange units,. and half-volume heat exchangers have all reached the international advanced level.

After years of accumulation of technology and practical application experience, Jiema has independent development capabilities and patented technology. It has been committed to the development and use of energy-saving and environmentally friendly heat exchange equipment, and has passed the TUV/ISO:14001:2004 environmental system certification, obtained the Guangdong environmental protection product certification.Independent research and development of plate and shell heat exchanger products and their automated manufacturing equipment, and obtained a number of national invention patents, using the international advanced fully automatic plasma welding process for product-heat core welding. and the produced plate/plate and shell type replacement Heaters. plate/plate shell heat exchange units,. and half-volume heat exchangers have all reached the international advanced level.