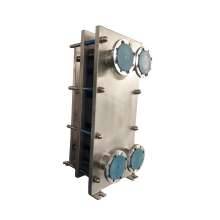

PLATE Frame Heat Exchanger FOR RAW CREAM/WHOLE MILK connects multiple plate packs together to form various flow channels, attempting to process the raw cream and whole milk all together. It is turnkey solution for the milk process line, with customized design heat exchange area.

For mechanical design and selection, we offer food grade stainless steel 316 plates(0.5mm), with NBR gaskets, and wide plate channels.

At the same time, heat exchange area is calculated based on user's operation details, including fluids inlet&outlet temperature, flow rate.

Moreover, fluids property also plays a significant role in terms of thermal calculation and design. That is to say, velocity, viscosity, pressure, and temperature are all essential factors for heat transfer.

Design Pressure: 12bar

Design Temperature: 120C

During the process line, customer also in need of introducing chiller water into the production line. And that's how we offer our one-stop solution. In addition to the Plate Heat Exchanger, we also customize Water Chiller, Cooling Tower, and related pipeline system for the plant.

Product Categories : Plate Heat Exchanger > Plate And Frame Heat Exchanger