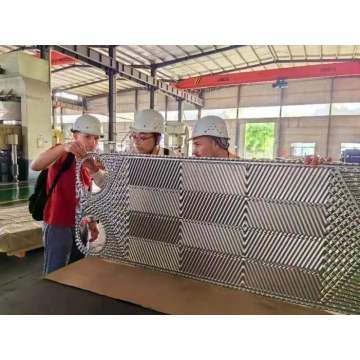

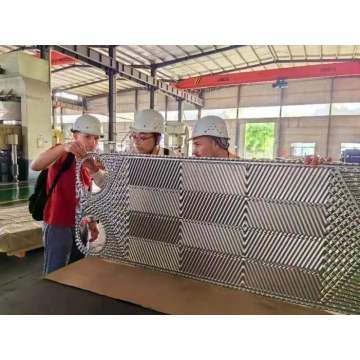

We already know about the

Plate Heat Exchanger, but are you familiar with its key component, the plate? Today we will introduce the commonly used materials of plate heat exchanger plates and their applicable conditions.

The raw materials of plate heat exchanger plates mainly include the following:

1. 304 stainless steel

This is the cheapest and most widely used austenitic stainless steel (such as food, chemical, atomic energy and other industrial equipment). Suitable for general organic and inorganic media.

2. 304L stainless steel

Corrosion resistance and uses are basically the same as type 304. Due to its lower carbon content and better weldability, it can be used in semi-welded or fully welded plate heat exchangers.

3.316 stainless steel

Suitable for general organic and inorganic media. However, it is not suitable for use with sulfuric acid. Since it contains about 2% Mo, its corrosion resistance in seawater and other chlorine-containing media is better than that of Type 304, and it can completely replace Type 304.

4.316L stainless steel

Corrosion resistance and uses are basically the same as type 316. Because the carbon content is lower, the weldability and corrosion resistance after welding are also better, and it can be used in semi-welded plate heat exchangers and fully welded plate heat exchangers.

5.317 stainless steel

Suitable for working conditions requiring longer service life than Type 316. Since the content of Cr, Mo and Ni elements is slightly higher than that of type 316, it has better resistance to crevice corrosion, pitting corrosion and stress corrosion.

6. AISI904L or SUS890L stainless steel

The cost-effective austenitic stainless steel takes into account both price and corrosion resistance. Its corrosion resistance is better than the above materials, and it is especially suitable for general acids and halides such as sulfuric acid and phosphoric acid. Has good resistance to stress corrosion, pitting corrosion and crevice corrosion.

7. Avesta 254SMO high-grade stainless steel

This is an ultra-low carbon high-grade stainless steel that has been improved on type 316 by increasing the Mo content. It has excellent resistance to chloride pitting corrosion and crevice corrosion, and is suitable for media containing salt water, inorganic acids and other media where type 316 cannot be used.

8. Avesta 654 SMo high-grade stainless steel

This is an ultra-low carbon high-grade stainless steel with higher Cr, Ni, Mo, and N content than 254SMO. It has better chloride corrosion resistance than 254SMO and can be used in cold seawater.

9.Titanium

Non-alloyed titanium is light in weight and has a relative density of 4.5. It can naturally form a passivation protective film and has "self-healing" properties if it is damaged once, so its corrosion resistance is better than stainless steel. Generally, it can be used for temperatures below 135°C. Sea water and salt water of various concentrations below 165°C. Titanium also has good corrosion resistance in organic acids below the boiling point (such as concentrated nitric acid, concentrated carbonic acid, etc.) and dilute alkali solutions.

10. Titanium-Palladium Alloy

This is the addition of a handful (0.12% -0.25%) of non-alloyed titanium, which significantly improves the corrosion resistance of titanium in acidic media (especially under less harsh conditions). For example, it has good corrosion resistance to nitric acid with a concentration of 70%, hydrochloric acid containing oxidizing ions, and electroplating solutions.

11. Titanium-molybdenum-nickel alloy This is alloyed titanium with added molybdenum (0.3%) and nickel (0.8%). It can be used in working conditions where non-alloyed titanium is not corrosion-resistant.

12.Nickel200

Pure nickel plate containing more than 99% nickel. Mainly used for high-concentration, high-temperature caustic alkali solutions. However, it is very sensitive to crevice corrosion caused by chlorides such as brackish water.

13.Hastelloy C-276

This is an expensive ultra-low carbon alloy - the main variety in C-group nickel-based alloys. It has good corrosion resistance; it is almost unaffected by Cl in low pH media; it has excellent corrosion resistance to various concentrations of sulfuric acid and is one of the few materials that can be used for hot concentrated sulfuric acid; it is widely used in organic acids , high temperature HF acid and a certain concentration of hydrochloric acid, phosphoric acid, chloride, fluoride and organic solvents.

![]() September 29, 2023

September 29, 2023 We already know about the Plate Heat Exchanger, but are you familiar with its key component, the plate? Today we will introduce the commonly used materials of plate heat exchanger plates and their applicable conditions.

We already know about the Plate Heat Exchanger, but are you familiar with its key component, the plate? Today we will introduce the commonly used materials of plate heat exchanger plates and their applicable conditions.