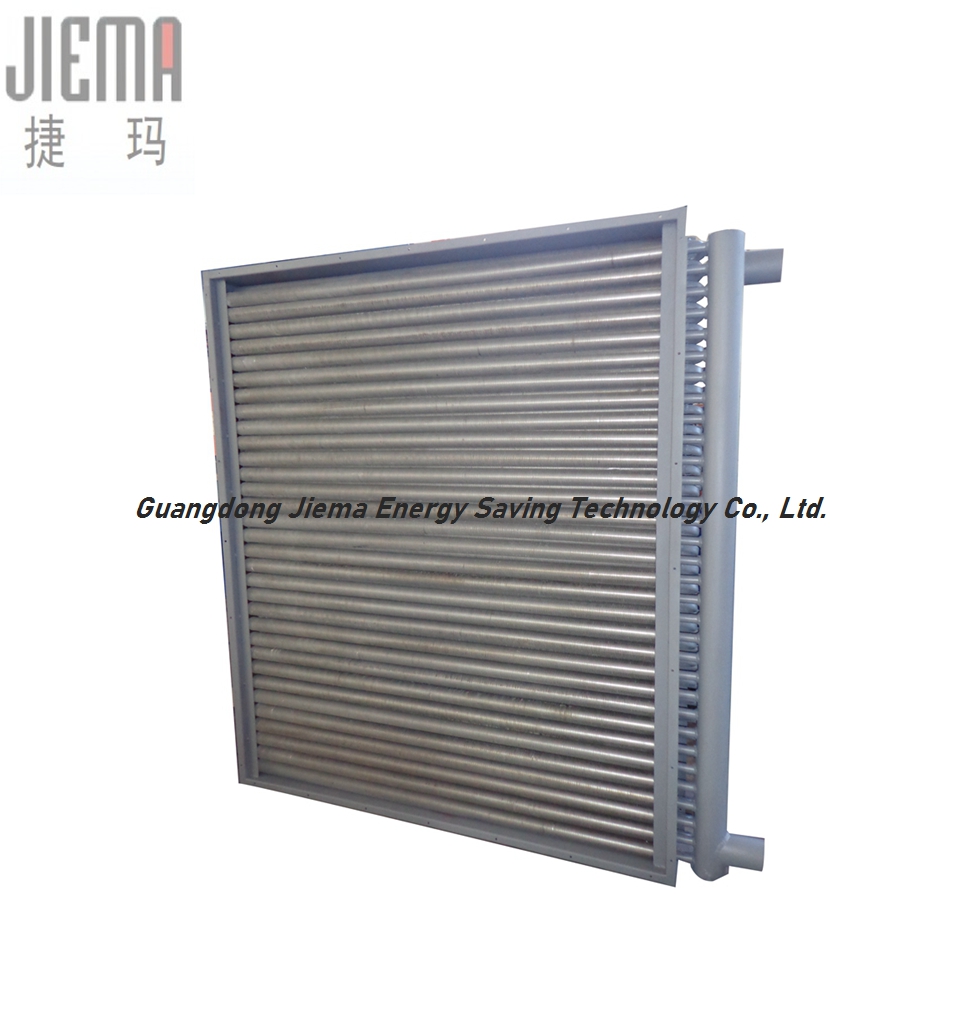

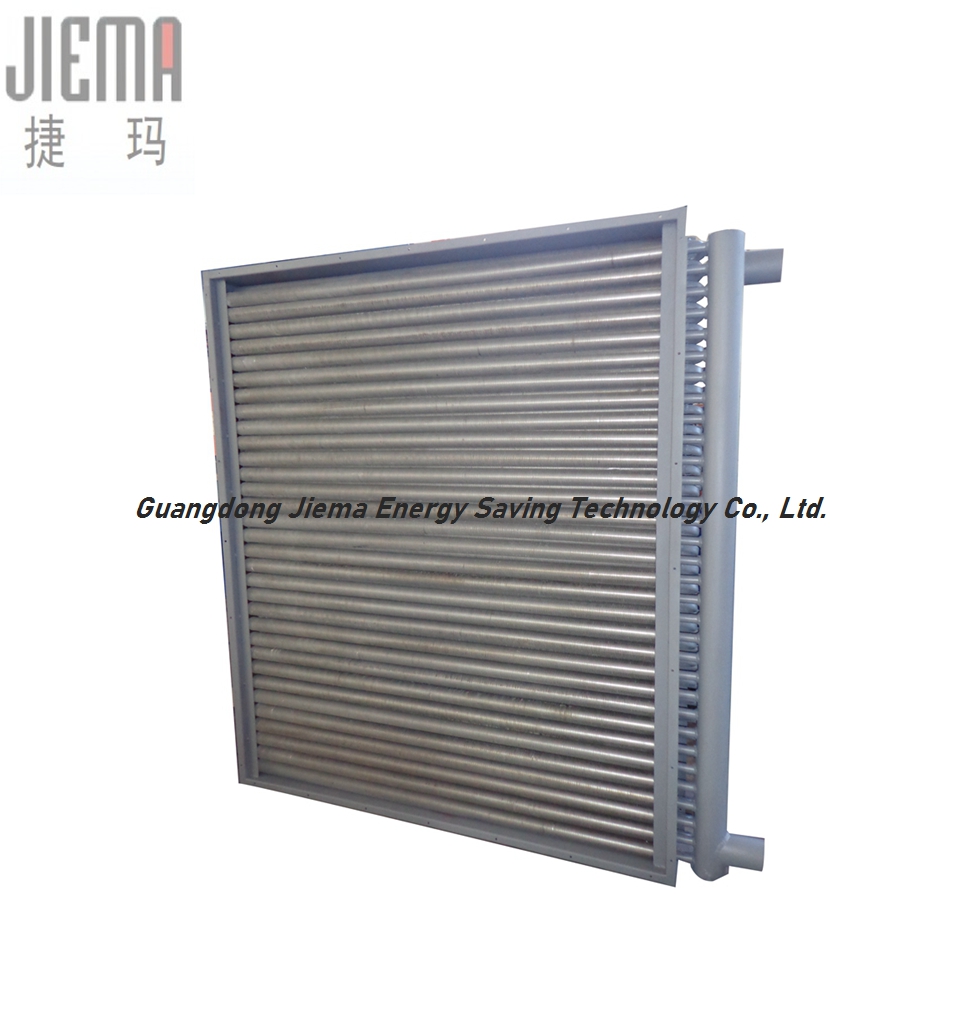

The Air To Air Heat Exchanger in the wood drying room is the equipment that heats the air in the room, raises the temperature and makes the drying medium with enough heat, or makes the water vapor in the room superheated and forms the atmospheric pressure superheated steam as the drying medium to dry the wood. It is mainly composed by finned tubes, cover frame, Flange connection, etc.

To release enough heat evenly;

To have the largest heat transfer coefficient and large heat transfer area;

To adjust the size of the heat released flexibly and reliably;

To be corrosion resistant, compact in structure, using less metal materials and low in cost

The hot source is variable:

Steam

As a clean, safe and cheap heat source, mainly used in indirect heat exchange wood drying equipment. The drying process conditions determine the required pressure and steam volume. If the plant has 0.6 ~ 0.8MPa steam, it can be heated to 150 ~ 160 ℃ through the heat exchanger drying medium (air, nitrogen or other gases). Theoretically, leaving the heat exchanger drying medium temperature is about 5 ~ 7 ℃ below the steam temperature.

Hot Water

If the temperature of hot water reaches 90 ~ 130 ℃, it can be for that it is considered to have a certain value of use. It can be used mainly for operating at a lower temperature of certain drying materials, such as the drying containing solvents or as an auxiliary heat source for preheating, through the form of heat exchange can make the drying medium to reach a temperature of 50 ~ 90 ℃.

Product Categories : Air Heat Exchanger > Finned Tube Heat Exchanger